The best solutions to check, control and test tripod and axle jacks with reliability, precision and safety

Our after sales and engineering teams have worked together for the best solutions to check, control and test tripod and axle jacks with reliability, precision and safety.

Decades of experience designing and manufacturing Ground Support Equipment, together with a strong and close cooperation with our customers in the daily maintenance of their jacks, have allow us to develop our portfolio of jack testers.

QUALITY & BENEFITS

- Ground support equipment manufacturer guarantee.

- Designed with the highest safety and quality standards.

- Long service life in operation.

- Certified calibration of load cells.

- Valid for all tripod and axle jacks existing in the market and from whatever manufacturer.

- Suitable for the 2 years test at 110% of the nominal load recommended by jack’s manufacturers.

- Articulated bars manufactured on high strength steel to adapt the dimensions to the jack to be tested.

- Locking pins with safety device to block against involuntary movements.

- Storage and transport case.

- LCD display integrated in a robust suitcase to register the load during test.

- Fixture structure with load cell integrated to reduce costs and maintenance required.

- CE certification and compliance with EN, ISO and IATA(AHM) regulations.

- OEM after sales service.

- At least 15 years of spare parts availability an in stock.

GSE

Product Finder

With our application you get a complete

overview of the products we offer for the

maintenance of your aircraft.

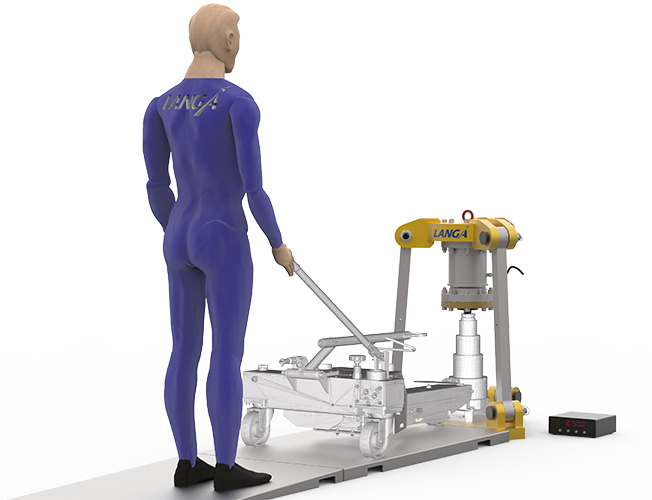

OUR JACK TESTER

Our jack tester family has two versions to perform periodic load test at 110%, a universal option to test tripod and axle jack and a special one only for axle jacks; and also a customized jack stand for the structural test at 150% of load capacity.

Jack testers

UNIVERSAL JACK TESTER

Designed to test all tripod and axle jacks from 5 up to 200t existing in the market and from any manufacturer, our universal jack tester is the best solution for periodic revision test at 110% of the nominal load of your jacks.

AXLE JACK TESTER

With is access ramp and auxiliary platform for easy positioning of all models, our equipment is valid, not only for the 2 years test at 110%, also for the structural one at 150% of nominal load of your axle jacks.

JACK STAND

Specially developed for customers with a wide range of units, our jack stand performs a reliable and safe load and structural tests of your tripod and axle jacks.

Find the most suitable jack tester for your needs

Three different versions adapted to your specific operation necessities.

| UNIVERSAL JACK TESTER | AXLE JACK TESTER | JACK TEST STAND | |

|---|---|---|---|

| Setting and functional check of safety valves |  |

|

|

| Hydraulic circuit test to detect and solve any leak |  |

|

|

| Load cells and gauges accuracy test |  |

|

|

| Cylinder load test at 110% nominal load for axle jacks |  |

|

|

| Cylinder load test at 110% nominal load for tripod jacks |  |

|

|

| Structural resistance test of axle jacks |  |

|

|

| Structural resistance test of tripod jacks |  |

|

|

Products in Stock

To reduce lead times to our customers we have the most common equipment in stock to give service to your aircraft immediately.

YOUR FASTEST GSE PARTNERProducts for Rent

Our rent alternative makes our equipment affordable in case of an urgent maintenance of your aircraft. Is the most flexible financial option and reduce your company investments.

EXPLORE THIS NEW GSE OPTION

PRODUCT FINDER

PRODUCT FINDER